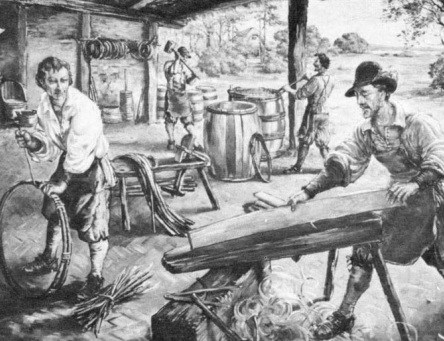

Let's begin our journey through discovering how an oak barrel is made by getting to know a bit about the man, the craftsman, the artisan behind it all, yes, our star... the cooper.

The cooperage industry dates back more than 2,000 years to the Gauls who used barrels to store and ship all kinds of things from food to gold coins and various dry goods.

The barrels were also called casks, tuns, kegs or hogsheads depending on the area of the world and their size. In the 1800s in Europe, a man skilled at making barrels was considered a very essential, key figure, as the variety of goods shipped and stored in barrels made him an indispensable craftsman suppling his product to all sort of trades.

In fact, although when we think of a barrel we automatically associate it to wine (or whiskey), in reality all sorts of foods were stored in barrels: sauerkraut was fermented and stored in them; fish, meats and some vegetables were dried and salted then stored and transported in barrels; most any item that could be contained for a length of time would be stored in a barrel to keep out pests; fragile items -such as eggs- would be packed in them among layers of straw to keep them cool and protected.

Originally barrels could be made using the wood of any tree that could be worked. With time oak became the preferred wood for wine and whiskey casks, as its finer grain allows the containers to be made waterproof.

Barrels had many advantages: they could easily be moved by rolling them down ship gangplanks; could have wheels and handles attached to them so a man could cart them about; smaller ones could be strapped onto a pack animal or strapped together to float behind a raft down a river; one could bury them in a stream or cool earth as refrigerating units; they were cut in half to feed or water stock, made into cradles for babies, or act as a large mixing bowls for any number of uses. Once modified in size and proportions, they became butter churns, buckets and even wash tubs.

One of the biggest uses for barrels in the nineteenth century was in the Turpentine Industry. Differing sized barrels were necessary for the storage and shipping of pitch, tar, turpentine and such.

The cooperage industry dates back more than 2,000 years to the Gauls who used barrels to store and ship all kinds of things from food to gold coins and various dry goods.

The barrels were also called casks, tuns, kegs or hogsheads depending on the area of the world and their size. In the 1800s in Europe, a man skilled at making barrels was considered a very essential, key figure, as the variety of goods shipped and stored in barrels made him an indispensable craftsman suppling his product to all sort of trades.

In fact, although when we think of a barrel we automatically associate it to wine (or whiskey), in reality all sorts of foods were stored in barrels: sauerkraut was fermented and stored in them; fish, meats and some vegetables were dried and salted then stored and transported in barrels; most any item that could be contained for a length of time would be stored in a barrel to keep out pests; fragile items -such as eggs- would be packed in them among layers of straw to keep them cool and protected.

Originally barrels could be made using the wood of any tree that could be worked. With time oak became the preferred wood for wine and whiskey casks, as its finer grain allows the containers to be made waterproof.

Barrels had many advantages: they could easily be moved by rolling them down ship gangplanks; could have wheels and handles attached to them so a man could cart them about; smaller ones could be strapped onto a pack animal or strapped together to float behind a raft down a river; one could bury them in a stream or cool earth as refrigerating units; they were cut in half to feed or water stock, made into cradles for babies, or act as a large mixing bowls for any number of uses. Once modified in size and proportions, they became butter churns, buckets and even wash tubs.

One of the biggest uses for barrels in the nineteenth century was in the Turpentine Industry. Differing sized barrels were necessary for the storage and shipping of pitch, tar, turpentine and such.

Many cooperages were -and still are- family owned and have been passed down through generations, so a cooper was usually trained by family tradition, from father to son. Many were Scots, while some were blacks who had been taught on the plantation where they lived. These men were skilled technicians, fashioning barrels from raw wood through many processes. Often they had to cut down a tree, cut it into boards, fashion the correct size and shape staves for a particular type of barrel and dry the wood before they could even start building a barrel. A keen eye was needed to assure there were no knots or weak grain in the wood used. Each stave must be as strong and well made as the next in order to guarantee quality. Selecting the right tree for the job was quite a talent and took a lot of experience.

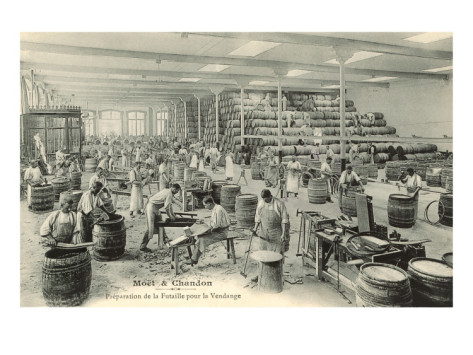

Nowadays, barrels are primarily used for the aging of wine and other spirits and coopers prefer to make cooperage out of French oak. The French perfected the craft of barrel making into an art form although good French oak was not available until the early 1900s. Prior to that time, French wineries used Eastern European oak to age their wine, primarily from Bosnia, Russia, Romania, Czechoslovakia and Yugoslavia.

Coopers still take a lot of pride in their ancient craft. Prize-winning, family owned Cooperages are recognized for their ability to control oak in order to bring about the desired, customized aromas and flavors, so valuable and desirable to winemakers.

Nowadays, barrels are primarily used for the aging of wine and other spirits and coopers prefer to make cooperage out of French oak. The French perfected the craft of barrel making into an art form although good French oak was not available until the early 1900s. Prior to that time, French wineries used Eastern European oak to age their wine, primarily from Bosnia, Russia, Romania, Czechoslovakia and Yugoslavia.

Coopers still take a lot of pride in their ancient craft. Prize-winning, family owned Cooperages are recognized for their ability to control oak in order to bring about the desired, customized aromas and flavors, so valuable and desirable to winemakers.

RSS Feed

RSS Feed